The other day, I gave a short presentation to a manufacturing client where I highlighted our work with Time-Series LLMs, which we use for advanced predictive maintenance to enhance efficiency and reduce downtime.

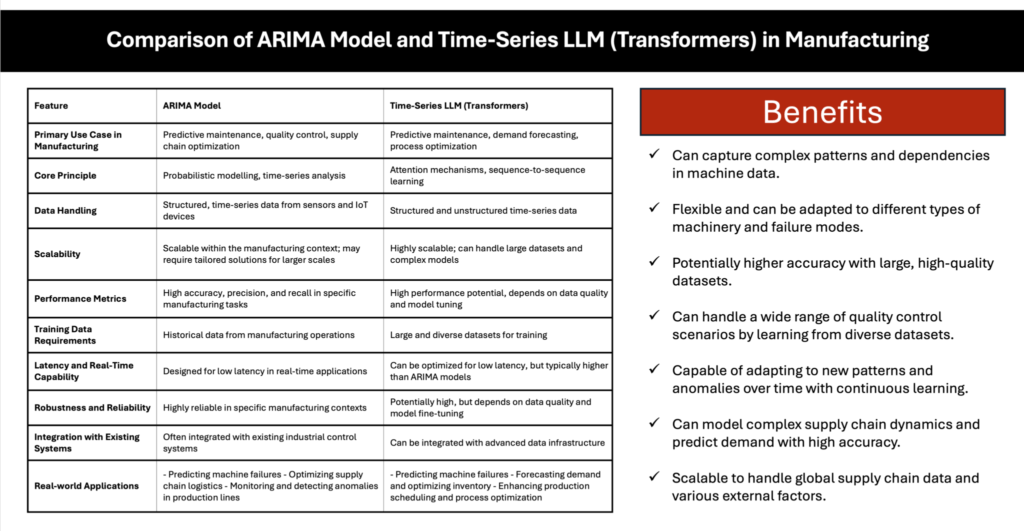

So, when comparing Time-Series LLMs (based on transformers) to ARIMA models, each has distinct advantages (see chart). ARIMA models often excel in predictive maintenance, quality control, and supply chain optimisation, providing high reliability and precision with moderate computational needs. However, Time-Series LLMs are quickly catching up, offering flexibility and scalability, and handling both structured and unstructured data for similar tasks, plus having the capacity to deal with far more external knowledge that is relevant to detect and prevent failures – which usually come from all sorts of data sources.

Whilst building predictive maintenance models with Transformers is less common than with ARIMA, the results are promising – very -, provided there’s sufficient data and grounding to avoid hallucinations. Ultimately, choosing the right model depends on specific manufacturing requirements and resources, but both approaches offer unique benefits to drive operational efficiency and innovation.

Here’s something new too: SOFTS: Efficient Multivariate Time Series Forecasting with Series-Core Fusion

https://github.com/Secilia-Cxy/SOFTS

Leave a Reply